2025 Construction Fleet Management: Top Tips & Tools

Dec 4, 2025•9m

2025 Construction Fleet Management: Top Tips & Tools

Key Takeaways

- Construction fleet management in 2025 demands real-time visibility, not guesswork. With multiple crews, vehicles, and assets spread across jobsites, staying on top of everything manually is no longer realistic — or sustainable.

- The biggest risks come from what you can't see. Poor tracking leads to delays, engine idle fuel waste, breakdowns, theft, and compliance headaches — all of which cut into your margins and slow down your projects.

- The right tools fix the right problems. GPS tracking for vehicles, equipment and assets, maintenance automation, driver alerts, and centralized reporting all reduce inefficiencies, increase accountability, and simplify the day-to-day work of fleet managers and field teams.

- One Step GPS gives construction fleets what they actually need. Fast installs, live tracking, real-time alerts, and U.S.-based support — with no contracts or hidden fees. It's everything you need to keep your fleet on track, without overcomplicating your ops.

You're on site by 6:45 a.m. — and by 7:15, someone's already asking where the skid steer is, why the dump truck hasn't arrived, and if the missing trench plates were ever loaded. Sound familiar?

When you're managing 50+ assets, rotating crews, and high-value equipment across multiple job sites, construction fleet management becomes a daily firefight. And in 2025, those fires burn faster — tighter margins, more compliance pressure, and zero room for guesswork.

So, what's the key to better construction fleet management in 2025?Real-time visibility, automated alerts, and simple tools that actually help you get ahead of problems.

This article walks you through:

- The biggest operational headaches construction fleets face today

- What poor management really costs (spoiler: it's more than fuel)

- Field-tested tips to cut downtime, boost safety, and stay compliant

- The tools that keep your jobsites moving and your teams accountable

6 Challenges of construction fleet management

Construction fleets are a different beast. You're not just tracking box trucks on highways, you're managing a mixed fleet of pickups, flatbeds, trailers, skid steers, generators, and specialty equipment scattered across active job sites. And each day brings a new round of logistical headaches to sort through.1. Jobsite chaos and vehicle coordination

Crews move fast, sites change weekly, and the margin for miscommunication is razor thin. If one truck is late or a key machine isn't where it should be, the ripple effect can stall a full day's work. Without real-time visibility, you're constantly fielding "where is it?" calls and playing dispatch roulette.2. Fuel waste and idle time

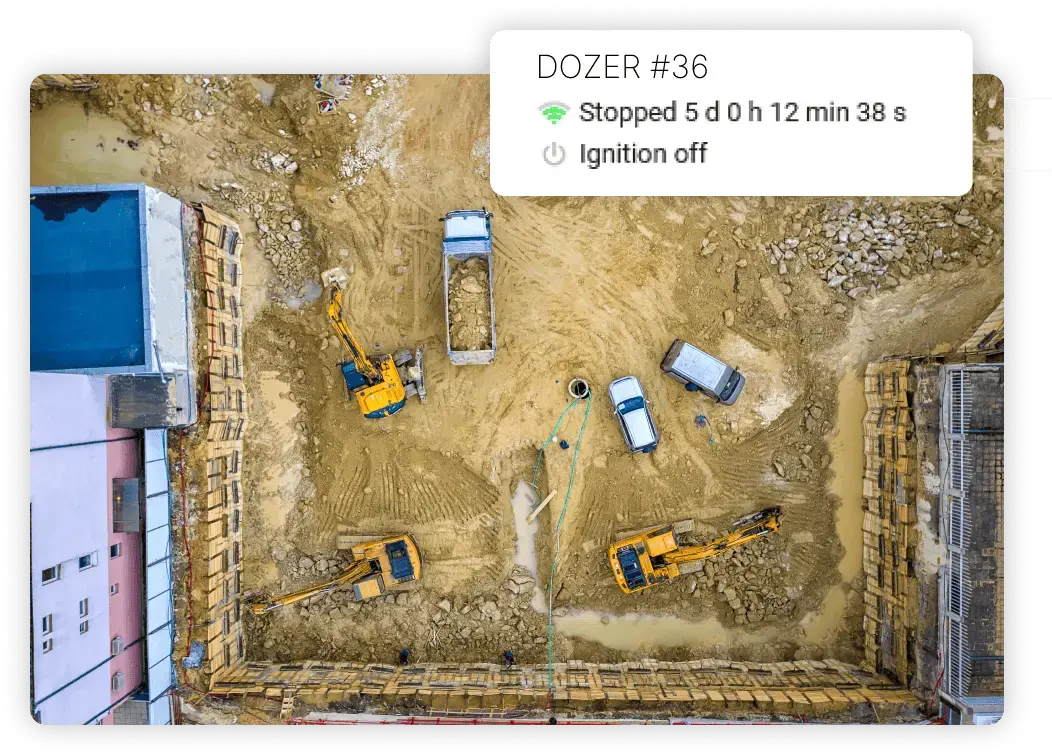

Construction vehicles idle. A lot. Whether it's waiting for site access or just poor driver habits, unnecessary idle time burns thousands in fuel and adds engine wear. Without GPS-based idling reports or alerts, this hidden cost goes unchecked and compounds daily.Pro buyer tip: One Step GPS flags excessive idling automatically and shows it by vehicle — so you know exactly where fuel is being burned and how to prevent it.

3. Lost or misused equipment

4. Maintenance delays and unplanned breakdowns

Construction gear takes a beating. But when there's no automated system flagging upcoming service or tracking mileage and hours, maintenance becomes reactive. That means breakdowns happen when you can least afford them — usually mid-job with no backup plan.5. Manual reporting and compliance headaches

DOT logs, timecards, inspections — you're swimming in paperwork. And if you're still relying on manual inputs, it's not just slow — it's error-prone. One missed record or late log can trigger costly compliance issues or insurance disputes.6. Limited visibility across multiple sites

With equipment and vehicles spread across several locations, it's hard to know what's on-site, what's in use, and what's sitting idle. Relying on daily phone updates or paper logs just doesn't cut it anymore — especially when you're managing $500K+ in mobile assets.

But it's not just about logistics — visibility is your first line of defense against theft. According to the NCBI, only about 23% of stolen construction equipment is ever recovered. Without live GPS tracking, your chances of getting back a missing skid steer or flatbed trailer are slim.

Pro Buyer Tip: One Step GPS gives you real-time visibility across every jobsite — including battery-powered and solar-powered trackers for non-powered assets like trailers, generators, and machine attachments. If something moves unexpectedly, you'll know instantly — and so will the police.

We had issues with theft of equipment and trailers, and we installed One Step GPS. It's been wonderful. We have caught thefts and recovered our property due to the GPS system. We also know where our equipment is at all times. Highly recommend!" — Shopper Approved reviewer

The negative impacts of badly managed construction fleets

Letting small inefficiencies slide may seem harmless in the moment — but over time, they bleed your margins, stress your team, and make it harder to deliver work on time and under budget. Here's how poor fleet oversight creates bigger problems down the line:Unpredictable job costing and budget overruns

When fuel usage isn't tracked, asset time-on-site is guesstimated, and maintenance costs hit without warning, you lose grip on actual project costs. Without accurate data, you're building bids on assumptions — and those assumptions often miss. That leads to underbidding, project overruns, and margin shrinkage you can't easily explain. Even worse? You don't know where the overages came from.

Construction firms working with razor-thin margins can't afford to be "close enough." Fleet data needs to be precise — or profitability takes the hit.

More downtime, fewer billable hours

When a vehicle breaks down on-site or an essential machine doesn't arrive until 10:00 a.m., crews stand around. You're still paying wages, but no work's getting done. And if your scheduler didn't know a machine was already booked at another site? That's hours gone, and the blame lands on your team. Compound that across jobs, and you're bleeding productivity daily — and paying overtime to catch up.

Downtime doesn't just delay work — it turns your most expensive resources into idle line items.

Liability and insurance exposure

No pre-trip inspection records? Incomplete time logs? Unmonitored driver behavior? That's a lawsuit waiting to happen — or at minimum, an insurance claim denial. If a dump truck is speeding in a school zone and you have no GPS proof to back up your training or oversight policies, your company is on the hook. The stakes are high in construction — one mistake can cost six figures and counting.

Good recordkeeping isn't just a compliance box. It's your legal defense.

Real-world example

When a truck was stolen from their office lot, Misty E. didn't waste time filing a report and hoping for the best. She opened One Step GPS, pulled the vehicle's exact location, and called the police to meet her there. Within three hours of the truck being reported missing, it was back at the office — and no insurance claim was needed.I was able to offer the police officer a full report on where the vehicle went the entire time it was gone, along with the video footage from our cameras that caught the picture of the guy that took it for the joy ride.

"Saved us thousands of dollars. Saved our company from filing an insurance claim. Made the police officer smile and do extra patrols still to this day because we were able to assist them. Made us happy that the service worked and continues to work for our company daily." — Misty E., HR Director

Poor client satisfaction and missed deadlines

When subs and equipment show up late or the wrong machine arrives for the job, it reflects poorly on your business. If it happens once, it's excused. Twice, it's a reputation risk. When poor logistics become a pattern, clients stop referring you and GC partners stop calling. In a relationship-driven industry, reliability isn't just nice to have — it's how you win your next job.

Fleet disorganization is a visibility problem. Clients don't care why — only that it keeps happening.

Slower growth due to inefficient scaling

As your fleet grows, so does complexity. Without centralized systems, scaling means adding more chaos — not more profit. You end up hiring additional coordinators, adding layers of approval, or buying duplicate equipment "just in case." None of that drives ROI. Growth becomes a burden instead of a multiplier.

If you can't scale your systems, you can't scale your fleet without losing control.

Burnout and turnover in field management

When foremen are fielding "Where's the trailer?" calls all day, chasing logbooks, or waiting on someone to drop off a replacement machine, they're not running the job — they're running interference. That day-in, day-out frustration adds up. Your best people won't stay if they're fire-fighting on their own all day.

Logistical friction wears down your crew long before they say it out loud.

Tips for successful construction fleet management

Most construction fleets don't fail because of one big mistake — they break down under the weight of dozens of small inefficiencies. The solution isn't hiring more managers or adding more meetings. It's getting the right systems in place to eliminate guesswork, reduce downtime, and give your team the clarity they need to act fast. These six strategies work because they solve the root causes — not just the symptoms.Tip 1: Use a fleet management platform that gives you visibility without the overhead

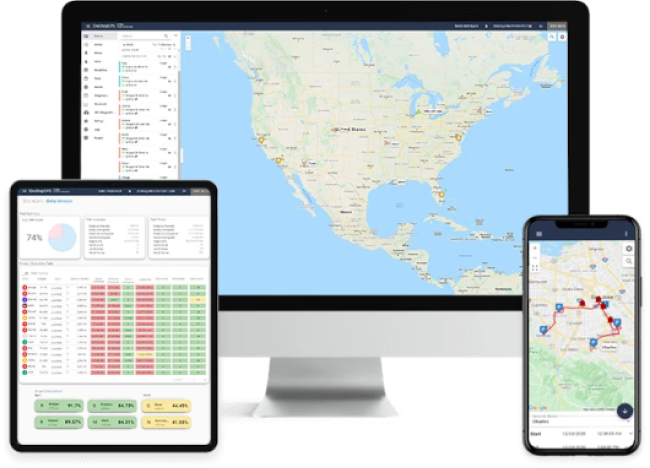

Construction job sites are hectic enough — you shouldn't have to manage your fleet by group text, gut instinct, or walkie-talkie updates. But that's exactly what happens when you don't have a real fleet platform in place. Vehicles go missing. Equipment gets double-booked. And you spend your mornings chasing location updates instead of running the day's schedule.One Step GPS puts everything in one place — without adding more complexity.You get GPS tracking with updates every 1-30, geofencing, engine idle and driver behavior alerts, automated maintenance logs, and plug-and-play install options. No contracts. No hidden fees. Just a clean dashboard that tells you exactly what's happening across your fleet — so you can take action faster.

We switched from a more expensive GPS provider (that also was difficult to get support from) and also tried a less expensive provider that was missing useful reporting and history recording. One Step GPS has been a great tool that offered what we needed and has been easy to get support from. I can easily track time on site and driving history. I highly recommend them to anyone looking for GPS tracking of their fleet." — Verified Shopper Approved review

Tip 2: Automate maintenance tracking

Construction vehicles don't follow fixed service intervals — they run hard, idle long, and vary by usage. That's why tracking engine hours and mileage is essential for keeping your fleet job-ready.

One Step GPS gives you the tools to stay ahead of breakdowns:

- Track mileage and engine hours in real time

- Set customizable maintenance alerts based on actual usage

- Get automated DTC (Diagnostic Trouble Code) readouts when faults occur

- Keep a centralized maintenance log for every asset

We have used other tracking programs in the past and have found One Step to be more reliable and by far superior in most every aspect for our company. The cost savings are substantial as well, coming in at less than 50% of other programs while delivering more consistent information without the time delay we experienced with the other programs. Minute by minute from day one — not like the others who wanted to charge extra to receive the same." — Verified Shopper Approved review

Tip 3: Monitor and reduce idle time

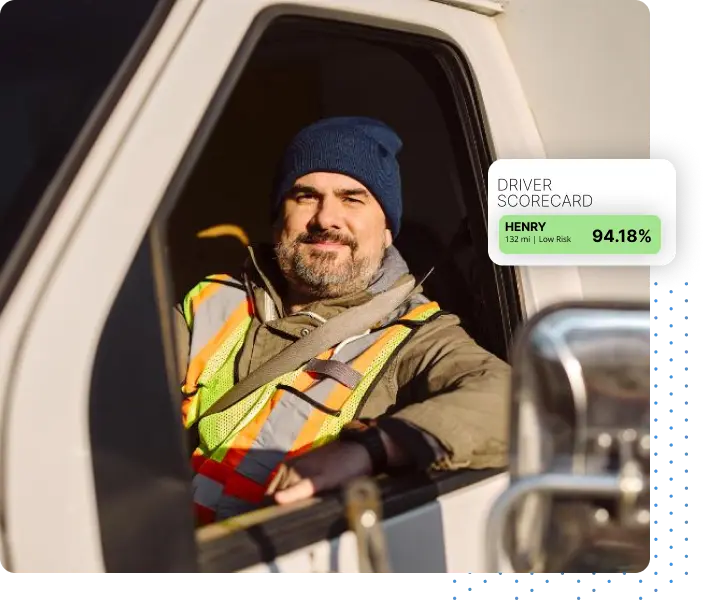

Left unchecked, idling kills fuel budgets and shortens engine life. The problem? Most managers don't know when or where it's happening. One Step GPS flags excessive idle time by vehicle and driver, so you can spot patterns and coach behavior. It's not about micromanaging — it's about saving thousands per month in avoidable costs and wear.Tip 5: Set up real-time alerts for job-critical events

From deliveries to departures, time matters on a jobsite. Our GPS tracking with customizable alerts lets you know when trucks arrive, when assets leave the site, or when vehicles deviate from planned routes. It's like having a field coordinator watching every vehicle — without needing a radio call every 10 minutes.Tip 6: Centralize reporting for compliance and accountability

DOT logs, vehicle inspections, fuel usage, time-on-site — with One Step GPS all your reporting lives in one system, everything gets easier. Audits are smoother. Billing becomes more accurate. Liability risk goes down. And your team can focus on building, not babysitting spreadsheets.A list of construction fleet management solutions

Managing a modern construction fleet takes more than a clipboard and a WhatsApp group chat. Below are the tools construction companies rely on to reduce downtime, stay compliant, and keep every asset pulling its weight — without adding more work to your day.

1. One Step GPS – GPS tracking, asset monitoring, and driver alerts

A full-service, contract-free GPS solution that's built for construction fleets. Track every vehicle and machine in real-time, streamline operations, transform safety, automate maintenance, and get 20+ alerts from speeding to idle behavior. Access ruggedized options to track any vehicle, heavy machinery or non-powered equipment, built for the demands of construction fleets.

Installation takes minutes, pricing is transparent, and support is in-house and U.S.-based — no contracts, no hidden fees, no nonsense.2. Maintenance management tools

One Step GPS includes a comprehensive maintenance suite built for busy fleets. You can:- Track engine hours, mileage, or time intervals

- Set custom alerts to flag upcoming service needs

- Log and manage maintenance records in a centralized dashboard

- Get automated fault code (DTC) alerts as soon as issues are detected

That means fewer surprises, better asset uptime, and no more missed service windows due to guesswork or lost paperwork.

Prefer to keep your existing tools? One Step GPS also integrates directly with platforms like Fleetio, Whip Around, and ManagerPlus — giving you flexibility without sacrificing functionality.

3. Jobsite communication platforms

On construction sites, poor communication creates costly delays — especially when equipment, vehicles, and crews are spread across multiple locations.

One Step GPS helps eliminate that guesswork.

With real-time tracking, geofencing alerts, and detailed trip histories, your team knows exactly where everything is — without chasing check-in calls or status texts.

Want more? Our integration marketplace offers solutions for time tracking, dispatch, and field communication — all built to work alongside your GPS data. And if you're using your own tools, our open API makes it easy to connect One Step GPS to your workflows with minimal dev work.

4. Equipment tracking solutions

When you're managing dozens of trailers, generators, light towers, and compressors, visibility is everything — especially on high-theft sites.

One Step GPS offers rugged, battery-powered trackers designed specifically for non-powered equipment. They're compact, long-lasting, and designed to withstand the rigors of construction environments.

For fleets that want to go even further, One Step GPS integrates with tool and asset tracking platforms like Clue and IVO Systems. That means you can connect location tracking with inventory systems, usage logs, and jobsite reporting — all in one streamlined view.

We have about 150 pcs of equipment that we track. Some are constantly, some are just pinged a couple times a day, and some are a combination. [One Step GPS] worked to find us the right mix and got us the equipment quickly. Every time I call with questions they are always answered in a timely and thorough fashion. They have been GREAT to work with." — Verified Shopper Approved review

5. Compliance and reporting software

Keeping up with DOT requirements, inspection logs, and equipment usage reports can be a full-time job. Look for systems that centralize logs, automate alerts, and simplify audits — or better yet, use GPS software that does it all in one dashboard. With One Step GPS, many construction fleets manage compliance reporting and time-based maintenance in a single interface.

Manage your fleet effortlessly with One Step GPS

Construction moves fast — and when you don't know where your assets are, jobs get delayed, margins shrink, and recovery becomes guesswork.

One Step GPS gives you the visibility and control you need.

Get real-time tracking (with updates as fast as every second), automated alerts, and rugged hardware that's quick to deploy — no contracts, no fine print. From pickups to trailers and everything in between, your entire fleet stays protected and accounted for.

Thousands of construction teams have already made the switch — not just for better tracking, but for fewer surprises, smoother operations, and U.S.-based support that picks up when it counts.

Ready to see what better looks like?Get full access to all of our real-time GPS tracking tools for $13.95/mo per vehicle or talk to our team to get any questions answered — no pressure, no contracts, just GPS that works.We switched from a more expensive GPS provider (that also was difficult to get support from) and also tried a less expensive provider that was missing useful reporting and history recording. One Step GPS has been a great tool that offered what we needed and has been easy to get support from. I can easily track time on site and driving history. I highly recommend them to anyone looking for GPS tracking of their fleet." — Verified Shopper Approved Review

Author

Mykael Korpash

Fleet and Tech writer

20,000+ of the world's fleets are monitored with One Step GPS

Author

Mykael Korpash

Fleet and Tech writer

Mykael writes on all things fleet and tech for One Step GPS. She has a nuanced knowledge of actual user experiences with fleet tracking software and of modern fleet issues and covers the most important topics in the space.