2025 Fleet Management Cost Analysis & Savings Options

Jan 12, 2026•11m

Key takeaways

- Fleet management cost analysis reveals exactly where your money is going — across vehicles, fuel, maintenance, insurance, driver behavior, and admin overhead — so you can fix what's draining your budget.

- A proper analysis helps you calculate true cost per mile and spot inefficiencies that don't show up in high-level reports, from underused assets to high-risk drivers.

- You can reduce costs by using a tool like One Step GPS to centralize tracking, automate alerts, monitor behavior, and catch small issues before they become expensive ones.

- Ongoing analysis turns guesswork into strategy — helping your fleet run leaner, safer, and more competitively, without sacrificing performance or putting more pressure on your team.

Are you sure your fleet costs are under control — or are expenses hiding in places you've stopped noticing?

Fuel spikes, unexpected repairs, rising insurance, underused vehicles, accidents, false claims — it adds up fast. And without a clear system to track and analyze it all, you're stuck guessing what's driving your spend.

A proper fleet management cost analysis gives you clarity. It shows where the money's going, what's driving it up, and how to fix it.

In this guide, we'll walk through the biggest cost categories to monitor, how to benchmark your fleet's spend, and practical ways to reduce it in 2025, using tools that actually make the job easier.

6 things to consider when analyzing fleet management cost

Fleet costs aren't just about how much you spend — they're about how easily small inefficiencies compound across dozens (or hundreds) of vehicles. Here's where to look first.Vehicle acquisition and depreciation

The cost of buying, leasing, or financing vehicles is one of your biggest upfront investments — but it doesn't stop there. Depreciation eats into value the moment a vehicle hits the road. If you're not calculating lifecycle costs (purchase price vs. useful life vs. resale), you could be overcommitting early and losing value on the back end.Fuel consumption and waste

Fuel is one of your biggest ongoing expenses — and one of the easiest to lose control of. Idling, poor routing, and risky driver habits all burn fuel fast. But fraud? That's harder to catch — and even harder to stop in time.

Without trip-level tracking and fuel usage tied to specific drivers and vehicles, you're left guessing where the burn is coming from — or whether it should be happening at all.

Pro Buyer Tip: Stop fuel fraud before it happensThe One Step GPS fuel card is the only fuel card on the market that can verify vehicle location in real time at the pump. When a card is swiped, real-time GPS confirms whether the assigned vehicle is actually present. If it's not, managers get alerted instantly — and can stop the transaction before the money leaves your account.

Combine that with idle time alerts, route tracking, and speeding reports, and you're not just monitoring fuel usage — you're actively preventing waste.

Maintenance and repair

Reactive maintenance costs more than scheduled upkeep, and it disrupts your entire day. But many fleets don't track repairs per vehicle, or tie maintenance costs to mileage and usage patterns. That makes it harder to spot high-cost outliers, overdue service, or vehicles that are costing more than they're worth to keep.Software, admin, and overhead

Multiple disconnected systems mean more license fees, more manual work, and more errors. When data lives in spreadsheets or across four platforms, your team loses time reconciling it — and small mistakes start costing real money. Streamlining your tools often cuts soft costs more than you'd expect.Fleet management cost analysis: how-to guide

A good cost analysis isn't about spreadsheets for the sake of spreadsheets. It's about gaining visibility into what's draining your budget — and finding the clearest paths to fix it. Here's how experienced fleet managers break it down.Step 1: Collect all cost data across your fleet

Start by pulling numbers from every category that affects your total cost of ownership:- Vehicle acquisition (purchase, lease, or financing)

- Fuel spend per vehicle

- Maintenance logs (both scheduled and reactive)

- Insurance premiums and claims history

- Driver-related expenses (pay, training, safety incidents)

- Admin costs and software subscriptions

Pro tip: When a vehicle burns more fuel and racks up more repairs, there's usually a deeper issue — often tied to how it's driven. With One Step GPS, you can see both behavior and maintenance alerts in one place. Add the fuel card, and you'll catch fuel misuse too — all from the same dashboard.

Step 2: Calculate cost per vehicle and per mile

Fleet averages only tell you part of the story. The real insights come from drilling down into cost per vehicle and cost per mile.

Start with a simple breakdown:

- Total cost per vehicle per month

- Total cost per mile driven

- Then compare those figures across your fleet

Step 3: Identify high-cost outliers and root causes

Now look for patterns. Which vehicles have:- Higher-than-average fuel costs?

- Frequent unscheduled maintenance?

- More driver behavior events (speeding, idling, etc.)?

Often, it's not just the vehicle — it's how it's used. Maybe one route causes more wear. Maybe one driver has more incidents. Or maybe an aging asset is no longer pulling its weight.

This is where your cost analysis becomes a decision-making tool, not just a report.

Pro buyer tip: Pinpoint your cost outliers in minutesWith One Step GPS, you can easily compare driver behavior, vehicle usage, and location history — helping you spot high-cost trends across your fleet without hours of spreadsheet digging.

Step 4: Look beyond direct costs

Some costs won't show up neatly in invoices — but they're real. Think:- Downtime caused by breakdowns

- Time lost chasing data across systems

- Admin hours spent manually logging inspections or generating reports

Step 5: Use the right tools to make this easier

Fleet managers who analyze costs manually — across spreadsheets and disconnected platforms — miss key insights and waste hours. That's where tools like One Step GPS come in.With GPS tracking, maintenance alerts, fuel usage reports, driver behavior monitoring, and compliance data all in one place, you're not stitching together a story — you're seeing the full picture in real time.

How to optimize & reduce fleet management costs

A proper cost analysis is only step one. The real value comes from knowing exactly where to act — and how to tighten operations without cutting corners. These are the most effective ways to reduce fleet costs in 2025.

Use a solution like One Step GPS to close cost gaps fast

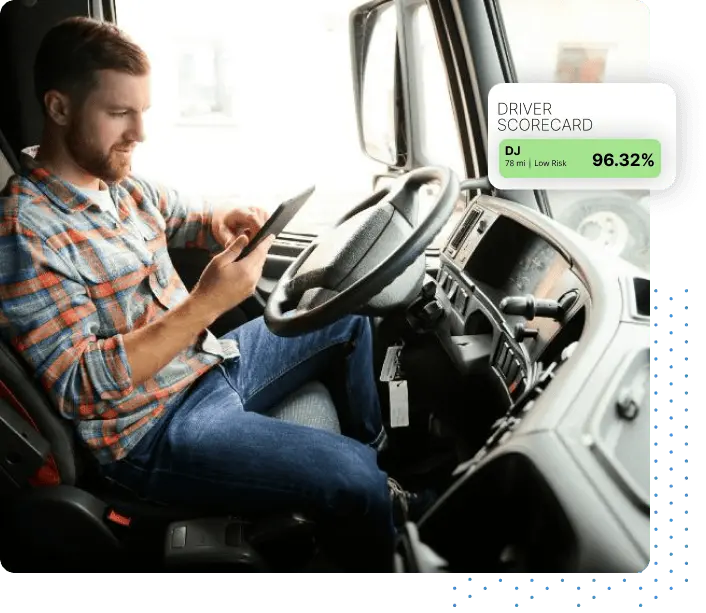

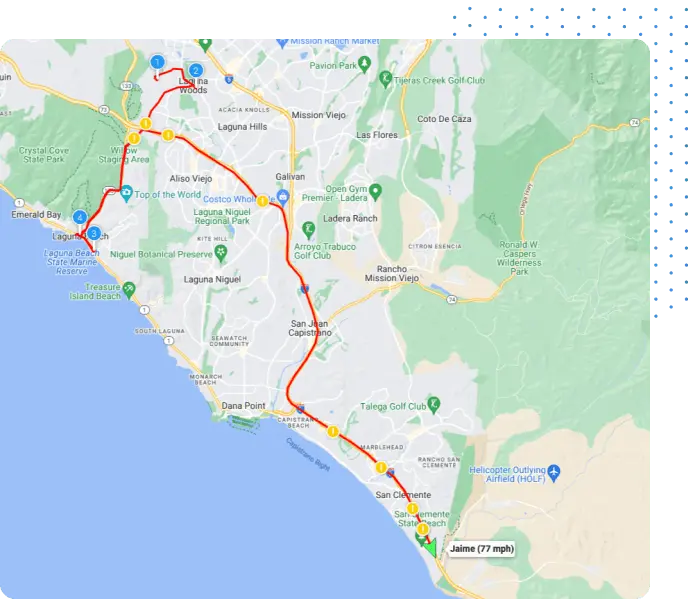

One Step GPS gives you full visibility into key cost factors like driver behavior, maintenance needs, asset utilization, and route efficiency — all from one easy-to-use dashboard.- Track real-time location, speed, idle time, and route history to reduce fuel waste and verify job completion.

- Monitor driver behavior (like harsh braking or speeding) to reduce wear, avoid accidents, and lower insurance risk.

- Set automatic maintenance reminders based on mileage or engine diagnostics — no more surprise repairs.

Plus, we partner with over 20 insurance providers to offer usage-based rates — so safer driving and smarter tracking can lead to real premium savings.

You don't need a full audit to start saving — One Step GPS shows you what to fix, where to act, and how to move faster.

This product is phenomenal. It allows me to track every movement of my vehicle and get alerts if my drivers go out of bounds or are excessively idle. I've also saved a great deal on my insurance premium." — Matt H., Owner and Operator, Capterra review

Implement preventive maintenance to avoid breakdown costs

A single breakdown can cost thousands — not just in repairs, but in missed jobs, tows, and rental vehicles. A preventive approach keeps costs low and uptime high.- Use mileage thresholds or engine fault codes to trigger alerts before issues escalate.

- Standardize inspection checklists so drivers can flag wear before it turns into failure.

- Schedule service during low-demand windows to reduce downtime impact.

Coach drivers with real performance data, not guesswork

Poor driving habits add up quickly: more fuel burned, more vehicle strain, more risk on the road. But generic lectures don't change behavior — actionable data does.- Scorecards show each driver how they compare on speeding, idle time, and harsh events.

Over time, even a 10% improvement in fuel efficiency or incident reduction translates to serious savings. One fleet of 200 vehicles — Communications Unlimited — saved over twenty thousand dollars in a single month using One Step GPS and the One Step GPS fuel card.

And it's not just about money — safer drivers mean better morale and fewer disruptions too.

Use route optimization to reduce miles and improve efficiency

Every extra mile costs fuel, time, and vehicle wear. Multiply that across a fleet, and routing inefficiencies can drain thousands per month.- Use GPS data to analyze route history and identify consistent delays or detours.

- Set geofences to verify job site arrival and departure — and eliminate dead time.

- Adjust dispatching based on real-world trends, not guesswork or habit.

Track trailers and equipment to reduce theft and waste

Lost trailers and stolen tools are still one of the most underreported cost leaks in fleet operations. And it's not always theft — sometimes it's just forgetfulness.- Add battery-powered trackers to trailers, generators, tanks, or other non-powered gear.

- Monitor dwell time to identify underused or misplaced equipment.

- Set location-based alerts to flag unexpected movement or items left behind.

The importance of fleet management cost analysis

Cost analysis isn't busywork — making those marginal gains is what separates average operations from truly efficient ones. Here's why it matters more than ever.You can't manage what you can't see

Even experienced fleet managers miss hidden costs when they're spread across systems or buried in routine. Without clear reporting, fuel creep, downtime, or unnecessary insurance premiums start to feel like "just part of the job" — when they're actually fixable.Small problems grow expensive fast

An extra hour of idling per vehicle per week? That's thousands in wasted fuel annually. A missed inspection turns into a breakdown. A trailer left behind goes unnoticed — until it's needed and missing. Cost analysis surfaces these slow leaks before they turn into budget-wrecking failures.Data turns gut instinct into strategy

Guesswork isn't scalable. When you calculate cost per mile, track behavior trends, and compare asset performance side-by-side, you make decisions based on fact, not feel. That's the kind of clarity that justifies upgrades, earns buy-in, and helps you plan long term.Strategic fleets run leaner and smarter

Regular cost analysis creates a feedback loop. You spot inefficiencies earlier, tighten workflows faster, and move from reactive problem-solving to proactive planning. And in 2025, that's the difference between staying competitive and falling behind.Optimize fleet management & reduce costs with One Step GPS

You've seen where the money goes — and where it doesn't need to.One Step GPS gives you the tools to track costs, tighten operations, and stop the waste — from real-time location data to driver scorecards, maintenance alerts, and asset tracking, all in one place.

Unlike your previous providers, we do away with the contracts, hidden pricing, and lousy support and keep the customer (you!) at the center of everything we do.

Want to run leaner in 2025? Start by getting your fleet under control — the smart way.

Frequently asked questions

Buy vs. lease vs. rent fleet vehicles

Buying gives you long-term ownership and resale value, but ties up more capital. Leasing offers predictable payments with mileage restrictions. Renting is best for short-term needs or seasonal spikes, but it's the most expensive option over time. Your fleet size, cash flow, and asset usage should drive the decision.How much does fleet management cost?

On average, fleets spend between $5,000–$8,000 per vehicle per year. This includes fuel, insurance, maintenance, licensing, and overhead. Poor visibility, inefficient routing, and reactive maintenance can push costs higher. With the right systems in place, many mid-sized fleets can trim 10–20% off their annual spend.What is fleet life cycle cost analysis?

It's a comprehensive view of what each vehicle really costs over its entire lifespan — including purchase price, financing, fuel, maintenance, downtime, and resale value. It helps you determine whether a vehicle is worth keeping, when to replace it, and which models deliver the best long-term ROI.Author

Mykael Korpash

Fleet and Tech writer

20,000+ of the world's fleets are monitored with One Step GPS

Author

Mykael Korpash

Fleet and Tech writer

Mykael writes on all things fleet and tech for One Step GPS. She has a nuanced knowledge of actual user experiences with fleet tracking software and of modern fleet issues and covers the most important topics in the space.